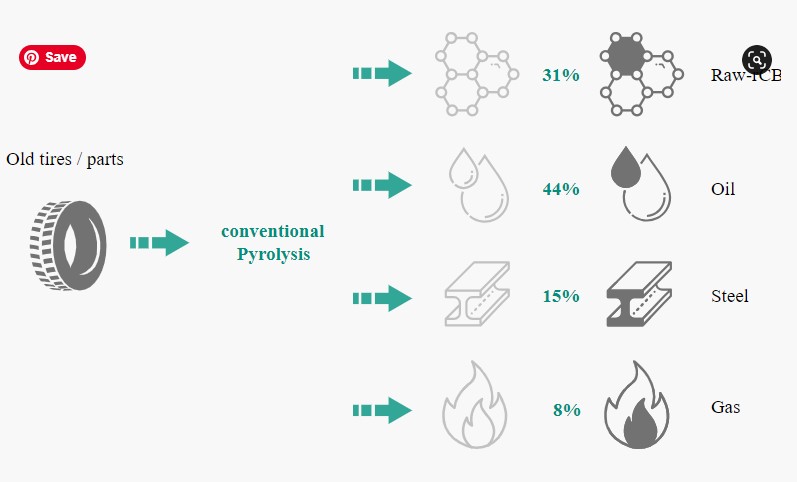

Recovered Carbon Black (rCB), a sustainable product obtained through the recycling of end-of-life tires and rubber products. This eco-friendly process involves pyrolysis, where waste materials are heated without oxygen, resulting in the formation of carbon black and the breakdown of organic compounds. The rCB we produce boasts high purity, consistent quality, and comparable performance to traditional carbon black.

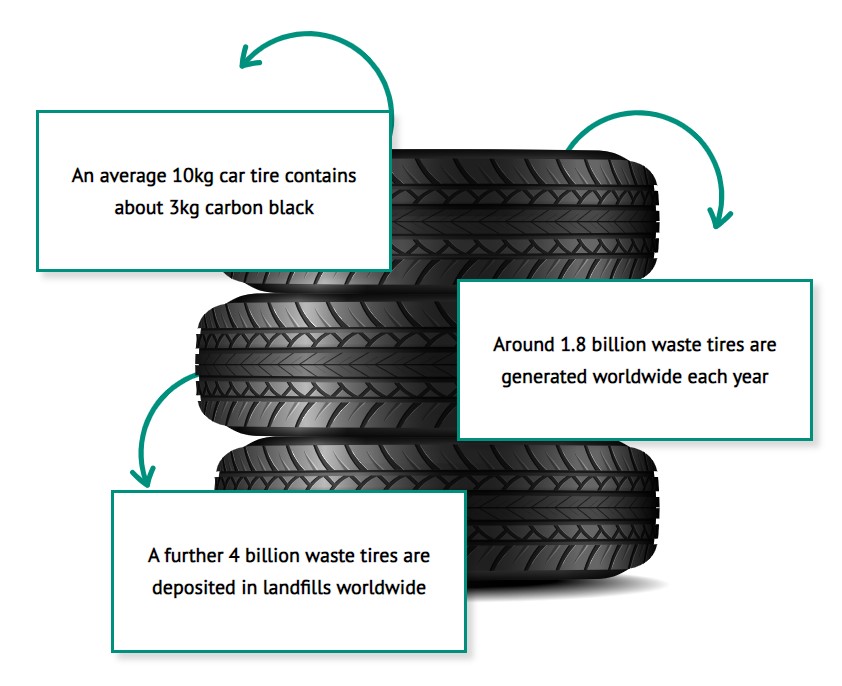

Recovered Carbon Black (RCB) Emerges As A Refined Solid Residue Resulting From The Thermal Decomposition Of End-Of-Life Tires (ELTs). This Resourceful Form Of Carbon Black Can Be Derived From Various Rubber Waste Sources, Although ELTs Prove To Be The Most Practical Due To Their Widespread Availability.

The Pyrolysis Procedure Effectively Reclaims Various Grades Of Virgin Carbon Black (VCB) And The Mineral Fillers Present In Rubber Compositions. Initially, The Output Of This Process, Known As “Char,” Undergoes Further Refinement Through Milling And Pelletization To Become Recovered Carbon Black (RCB). Despite Containing Approximately 20 Percent Less Carbon-Based Material Compared To Virgin Carbon Black Due To Mineral Inclusion, RCB Maintains Its Premium Quality And Offers Diverse Potential Applications.

Experience The Exceptional Performance Of Recovered Carbon Black (RCB) From Jisha Export, Mirroring The Quality Of Various Grades Of Virgin Carbon Blacks Commonly Used In Tire Production. Notably, RCB Boasts A Carbon Footprint Over 80 Percent Lower Than That Of VCB, Aligning With Sustainable Practices And Environmental Consciousness.

Discover The Pervasive Role Of Carbon Black In The Manufacturing Of Black-Colored Rubber Or Plastic Items. With The Tire Sector As Its Primary Consumer, Nearly 70% Of Global Carbon Black Production Caters To Tire Manufacturing. An Additional 20% Serves The Production Of Specialized Rubber Items Such As Seals, Molded Components, And Vibration Mitigators. The Remaining 10% Plays A Vital Role As A Foundational Input In The Production Of Plastics, Toners, And Inks. Explore The Diverse Applications And Significance Of Carbon Black In Various Industries.

Recovered Carbon Black Is A Sustainable Alternative To Virgin Carbon Black. There Is A High Interest In RCB From Tires, Manufactured Rubber Goods, Plastics And Pigment Industries.

About 1.5 Tons Of Fossil Fuel Raw Materials And Large Amounts Of Water Are Used To Produce 1 Ton Of Carbon Black. During The Furnace Process, Approximately 2.5 – 3.0 Tons Of CO2 Emissions Are Released Per Ton Of Carbon Black Produced. As A Result, The Production Of Carbon Black Contributes Greatly To The Release Of Greenhouse Gases And The Associated Problems. In Order To Reduce CO2 Emissions And The Consumption Of Fossil Raw Materials And Water, Processes For The Efficient Recovery Of Carbon Black Is Developed.

Adopting Recovered Carbon Black (RCB) Results In A Remarkable Reduction Of Over 80 Percent In CO2 Emissions Per Ton Of Produced Carbon Black. To Put It Differently, If RCB Were To Substitute Just 10 Percent Of VCB Production, The Global Annual CO2 Emissions Would Witness A Remarkable Decrease Of 2.7 Million Tonnes.

Copyright © Jisha Export. All Rights Reserved.